After your test-and-learn experience in a pilot, you’ll be able to start picturing the transition to an EV fleet, whether that means acquiring a fleet of EVs or implementing EVs across new vehicle classes and types.

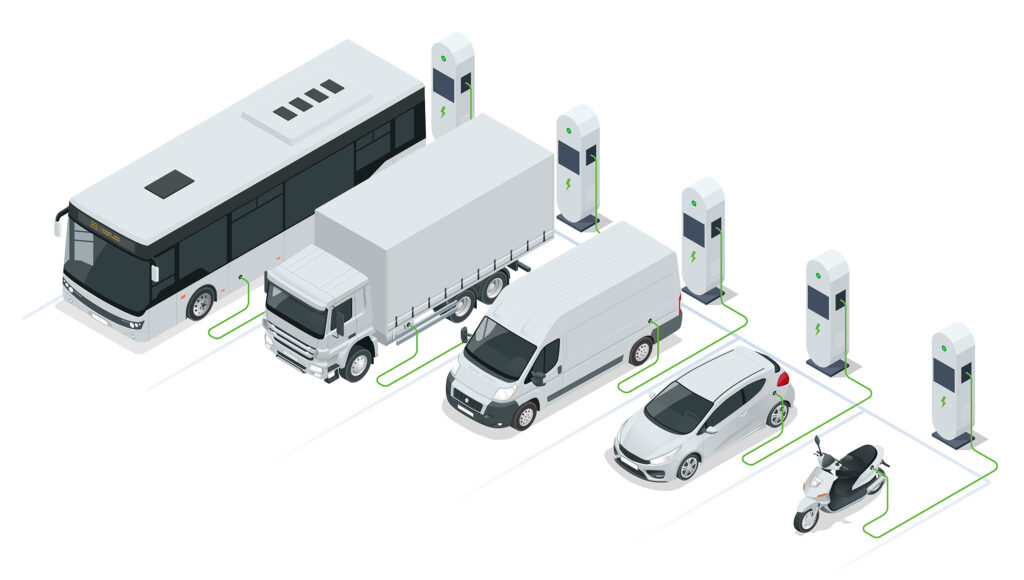

The three big areas that every EV fleet needs to plan for are:

- The charging infrastructure

- The vehicles

- The people who will drive them.

Here are some tips to help for things to consider and ways to keep costs down.

Charging infrastructure

Adding the charging infrastructure (i.e., the charging hardware, installation and power) you need for an EV fleet can be the biggest investment in the electrification process1 in terms of both time and money. You’ll find more on this in the next lesson dedicated to charging.

Cost (and charger) sharing

Consider sharing the cost of installing chargers with your bigger customers, which might be especially relevant for logistics companies. You may even consider installing chargers at their facilities. If your trucks are loaded at the customer’s operation overnight, they could be charged while they are loading, or waiting to be loaded. It’s a solution that benefits both partners, says Marcon-Miratech fleets consultant Pierre Ducharme. IKEA, for instance, has set up charging for several of its Canadian carriers at its sites. IKEA is able to speed up its zero-emissions delivery strategy, eliminate fuel surcharges in its carrier contracts and benefit from carbon credit generation on the infrastructure.

Plan for expansion

If you do not own your facility, be sure that your plan for growth factors in the expenses of a major charger installation at a leased facility. If that lease ends you’ll have to either leave the chargers behind or move them, incurring setup costs all over again.

Be portable

Try to install wall-mount type chargers whenever possible, Ducharme says. They are moveable and do not require expensive engineering and trenching, pouring concrete and repaving that permanent chargers do. There is also typically a three- to four-month timeline to complete the installation of fast chargers,2 so you need to take that into account as well. But if you can’t use the wall-mounted style, do the earthworks all at once to avoid redundant costs for trenching and wiring.

“Do things with the future in mind – or consider installation options without trenching. Solutions such as elevated platforms allow for higher powered chargers to be installed without necessarily having to trench through a site. It’s a useful solution for brownfield projects.”

— Matthew Bartolone, ABB E-Mobility

Consider energy management

It’s important to not only know how much energy you’ll need, but when and at what intensity. To take advantage of cheaper off-peak rates, you may need to install accumulators (big batteries) that recharge when power rates are low and then use them to charge your vehicles. There’s also the challenge of knowing when to move from Level 2 chargers to DC Fast charging. DC Fast chargers can cost more than EVs themselves, but charging a higher volume of vehicles may require faster charging. Doing the math here is critical.3

Vehicles

Look at vehicle lifecycle

Plan out past the lifecycle of your current assets. Keep a close eye on the vehicles that are coming to market and find a balance between availability, cost and meeting your duty cycle requirements.

Keep an eye on new vehicles entering the market

Daimler Rizon, Bollinger Motors and Isuzu all introduced trucks to the Canadian market in 2024/25. Chevrolet, Ford and Rivian all offer electric pick-ups. And electric vans are now available from Ford, Chevrolet, Mercedes-Benz, Ram and other well-known automakers. As more vehicles become available, both vehicle selection and range options are becoming more fit for purpose for fleets of all kinds.

People

Train and reward your people

One potential challenge of electrification is that people won’t change their driving habits, which can mean your vehicles won’t achieve the range potential you planned for. Ducharme advocates using a carrot-and-stick approach to getting your employees to adopt good EV driving habits. A telematics system will give you insights into who does what behind the wheel. You can reward good performance and gently correct those who are lagging.

Check what you’ve learned about suitability assessments and pilot projects in the quiz below, then move on to Lesson 4: How you fuel an electric vehicle.

Reproduction of any or all of this material is strictly prohibited without permission. Please contact fleets@electricautonomy.ca for inquiries. Copyright © 2025 – Electric Autonomy Canada – ArcAscent Inc. – All Rights Reserved

Want to learn more? Sign up or log in so you can track your progress, earn a course certificate and receive exclusive invitations to our live learning sessions.